1 Functionality of Optimizers

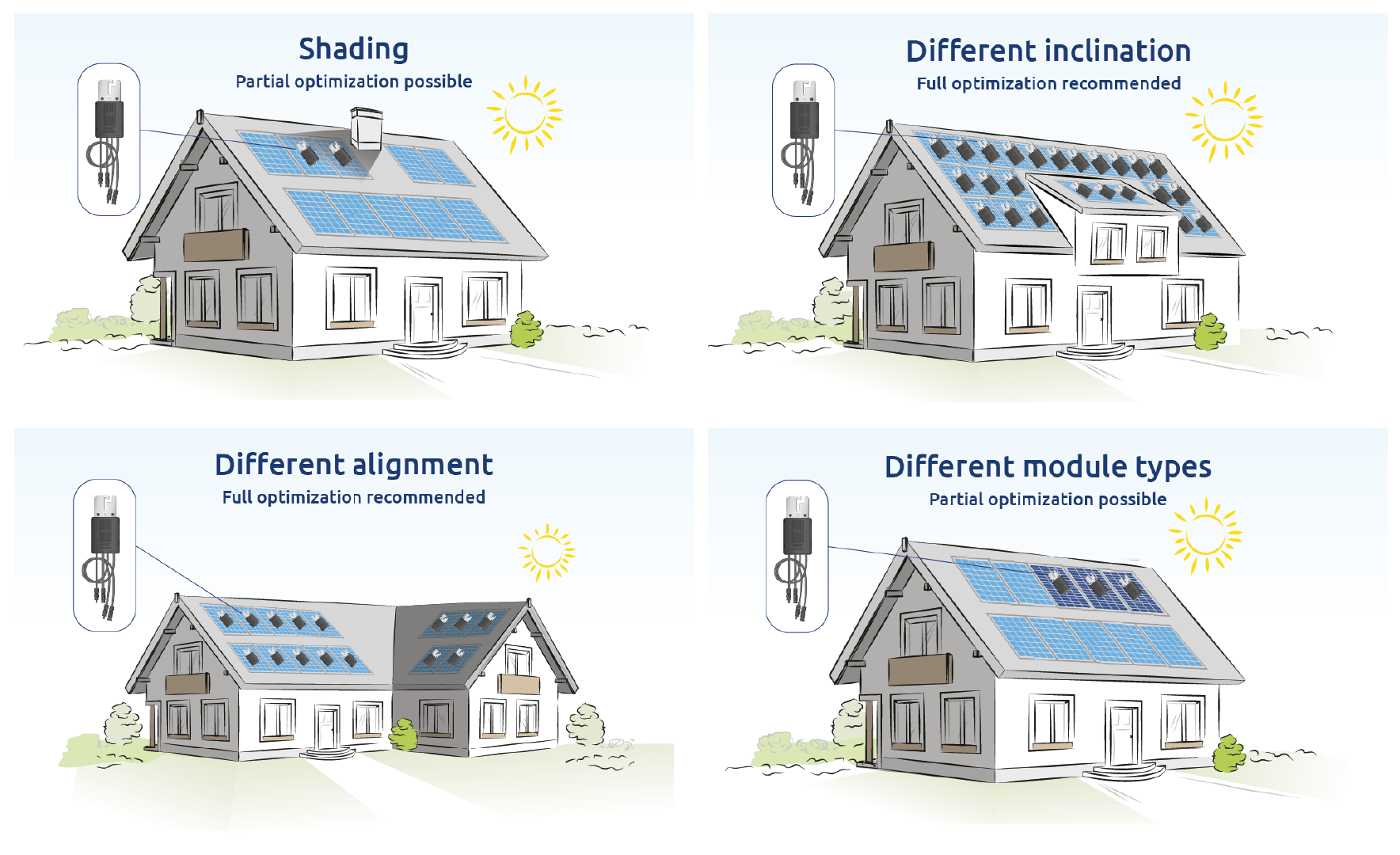

Optimizers solve the problem of uneven irradiation within a string, specifically in cases of shading, different module orientations or tilt angles, as well as when different types of modules are used.

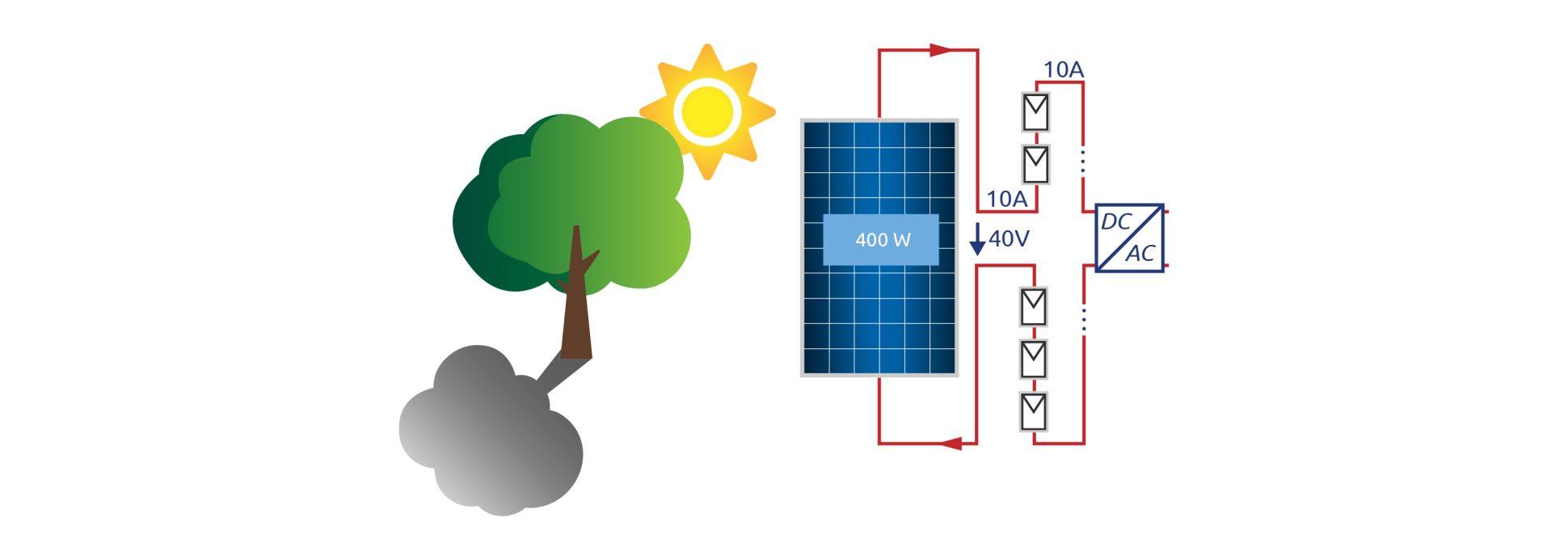

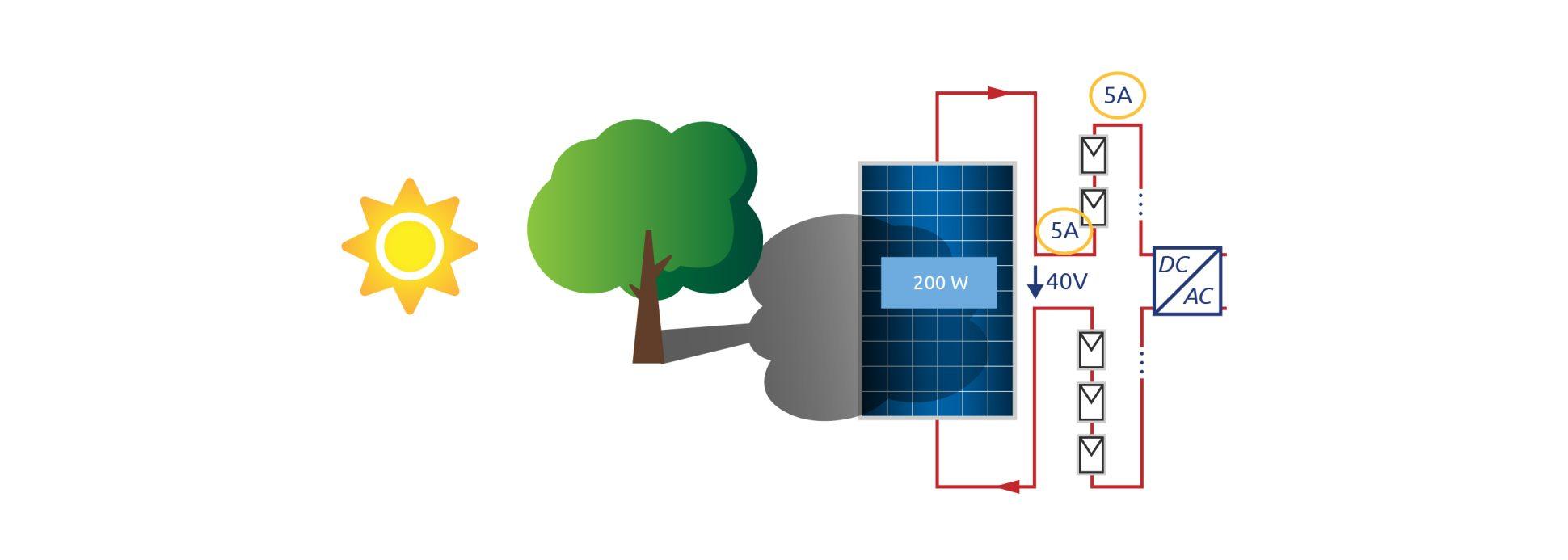

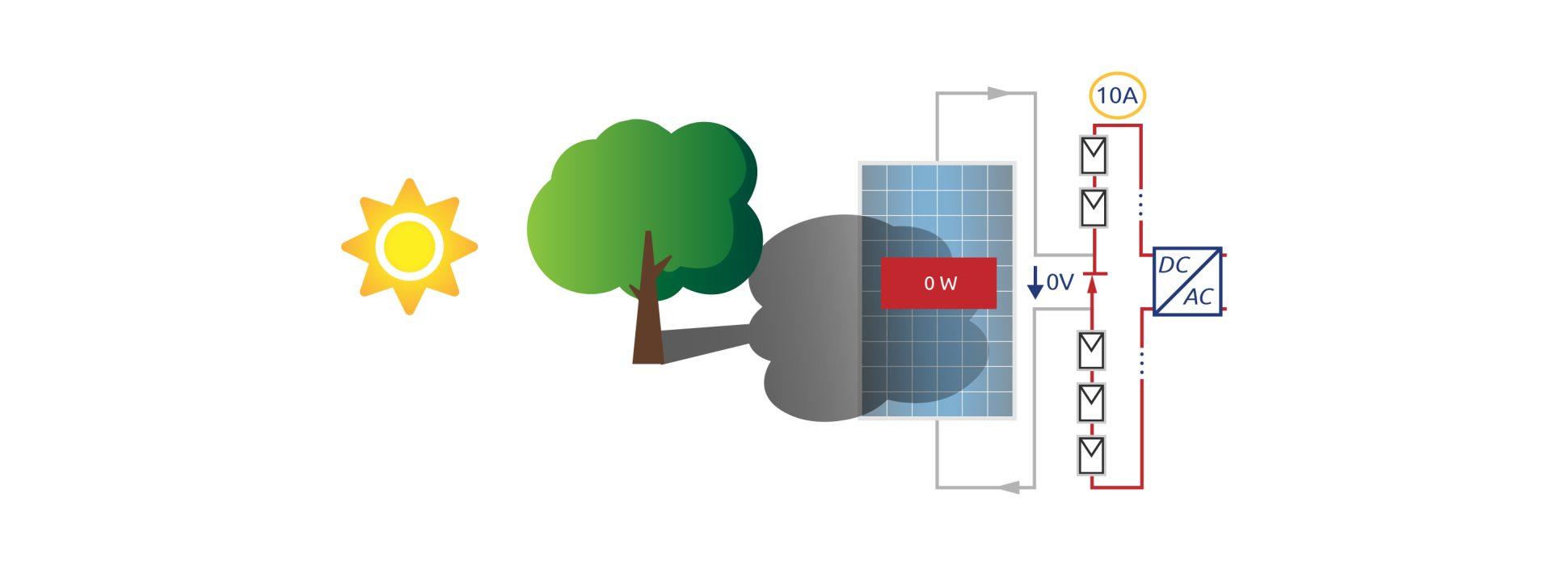

If certain modules within a string are exposed to less sunlight (e.g. due to shading), these modules generate a lower current. The module voltage remains unchanged. As a result of the reduced current, the module’s power output decreases (P = U × I).

Reaction 1:

Since the current in a series circuit is the same everywhere, the module with the lower current limits the other modules in the same string, which would normally be able to produce more current and therefore more power.

Reaction 2:

Inverters with global MPP tracking ensure that modules producing lower current are bypassed by activating the bypass diodes in the module. This means that modules or parts of modules that generate less current due to reduced irradiation are removed from the system.

The advantage is that the remaining modules are no longer dragged down and can once again feed their full power into the system.

The disadvantage is that the bypassed modules can no longer feed the energy they could still generate despite the impairment into the system (power loss). Since this energy cannot be fed into the system and instead circulates through the bypass diodes inside the module, it is converted into heat. This manifests itself in the form of hotspots on the cells of the affected module. The formation of hotspots on the cells can often cause them to burn out and fail over time, which can significantly impair the long-term performance of the modules.

To counteract these impairments, we developed our BRC power optimizers. They resolve all of the issues mentioned in the most efficient way. This ensures that you always achieve maximum yield, even with complex rooftop installations.

Further information on the application scenarios can be found in our video series at the following link:

https://www.youtube.com/playlist?list=PL6AuvlotuhZ24cln9I7wGvmwmJEfYxbCe

Our optimizer is a power-electronic circuit that can adjust the current-to-voltage ratio of a module so that a module with lower irradiation, and therefore lower current, is boosted to the same current level as the other modules in the string. The optimizer achieves this using a so-called buck converter, which lowers the voltage so that the current at the output can be increased proportionally to match the string current. This ensures that no module slows down the others. In return, the module’s voltage is reduced, which leads to a lower string voltage when an optimizer is active. This mechanism ensures that each module can continue contributing its energy, resulting in more energy production than without an optimizer.

To simplify things, here is an example:

How is the Power Optimizer connected?

The optimizer is connected quickly and easily via plug-and-play. A step-by-step guide can be found in our video tutorial:

With global MPP tracking, the inverter continuously searches for the optimal operating point (MPP) within its string. This is recalculated at regular intervals. Modules with lower irradiation would reduce the string current, so the inverter’s MPP tracker counteracts this by increasing the required current to find the maximum power point (MPP). When some modules produce more current than others in the string, the modules with lower current are bypassed by activating their bypass diodes (the diodes become conductive). This prevents the lower-current modules from reducing the string current. However, the remaining energy from diffuse light in the bypassed modules is converted into heat. Hotspots form on the cells, which can damage the module over time and reduce its lifespan.

BRC optimizers prevent the activation of bypass diodes and thus the formation of hotspots, because the energy can continue to be fed into the system. Instead of bypass diodes being activated by global MPP tracking, the optimizer activates and ensures that the inverter’s required current flows at the optimizer output. The remaining energy from diffuse light can continue to be used, and no hotspots are formed.

In principle, every electronic device emits electromagnetic signals during operation. For photovoltaic devices, there are standards that clearly define the limits for our products. All of our devices comply with these limits. Further information on the standards we adhere to can be found in the datasheets of our products.

In darkness, our optimizers are switched off and do not generate any electromagnetic signals, since the modules themselves produce no power without light.

A bypass diode is only activated when the voltage across a module reverses. This occurs when a module or cell is required to provide more current than it can deliver. In this case, the cell acts as a consumer, and a hotspot forms at that location on the affected module. Therefore, an active bypass diode does not prevent hotspot formation. The optimizer, on the other hand, prevents hotspots by boosting the current to the string level, ensuring that the remaining energy is fed into the system instead of being converted into heat.

2 General Questions About Our Optimizers

Warranty on Optimizers:

We provide a 25-year product warranty on the purchase price of the optimizers.

In addition, you have the option to receive an extra replacement allowance (applicable only to installers with a registered installation business) in the event of a warranty claim. You can obtain this by registering in our BRCademy and earning the required certificate through small e-learning courses. In the event of a warranty claim, you will then receive a predetermined amount as a replacement allowance in addition to the product warranty.

Warranty on BRConnect:

We provide a 10-year product warranty on the purchase price of the BRConnect devices.

– Easy installation and connection via plug & play; partial optimization possible

– For optimizers with data transmission → data is transmitted via Power Line Communication (PLC) / DC line, not via radio

– Can be used independently of the inverter https://brc-solar.de/en/power-optimizer-en/compatible-inverters/

– Most efficient technology (patented inactivity of the power electronics when no optimization is needed)

– 20× faster response to shading; efficient optimization using GaN transistors

– Long-life electronics (German engineering)

In general, all limits specified in the optimizer datasheet must be observed, in particular:

– The module’s open-circuit voltage must never exceed the optimizer’s maximum allowed voltage, even at the lowest temperatures.

– The module’s MPP current must not exceed the optimizer’s maximum allowed current under standard test conditions (STC).

– The module’s power must not exceed the optimizer’s maximum allowed power under standard test conditions (STC).

– The string current must not exceed the optimizer’s maximum allowed current. When the string is fully equipped, the inverter determines the string current, not the module. Therefore, the MPP tracker in the inverter must not exceed: 15 A (M500), 16 A (M600‑M, M600‑E), or 18.5 A (M700‑E) if more than 50% of the modules in the string have an optimizer.

You can find the specific values in the datasheets of the respective products. Datasheets, installation instructions, and other documents are available here:

The self-consumption of the optimizers consists of the idle consumption and the consumption during optimization.

The idle consumption is well below 1 W and occurs when the optimizer does not need to operate, for example, if it is not shaded. The maximum efficiency per optimizer can be found in the respective datasheets.

Line losses during operation depend on the current flowing in the string and on how much the optimizer needs to boost the current.

The metal plate on the optimizer is used solely for mounting purposes. It does not serve for cooling or grounding. There is no direct connection between the mounting plate and the electronics inside the optimizer.

On our optimizers, we use original MC4 connectors from Stäubli. Therefore, they may only be connected with original MC4 connectors from Stäubli. Stäubli also considers MC4 Evo 2 connectors to be compatible with the original MC4 connectors, so these may also be used.

3 Specific questions about Power Optimizer m500

The Power Optimizer M500 was discontinued in August 2025 and is no longer being produced. However, some remaining stock may still be available from dealers. The direct successor is the Power Optimizer M600‑E.

The M600‑E is based on the proven features of the M500 — including the patented inactivity, the simple plug‑and‑play connection concept, inverter independence, and the ability to perform partial optimization starting from a single optimizer. In addition, the M600‑E offers higher performance and is designed for a maximum input power of 600 W.

Below is a comparison of the two optimizers:

| M500 | M600-E | |

| Maximum input current | 15A | 16A |

| Efficiency | 99,50% | 99,50% |

| Input power | 570W | 600W |

| Rated current | 15A DC | 16A DC |

| Short-circuit current | 17A DC | 20A DC |

| Absolute max input voltage (at -40 °C) | 65V DC | 70V DC |

| Output power range | 0W bis 570W | 0W bis 600W |

| Input voltage range | 16-65V DC | 16-70V DC |

| Dimensions (W×L×H) | 78 mm x 161,5 mm x 30 mm | 78 mm x 145 mm x 22 mm |

| Slim design for flat modules | ✓ | |

| Plug & Play | ✓ | ✓ |

| Patented inactivity of power electronics | ✓ | ✓ |

| 25‑year product warranty (from commissioning) | ✓ | ✓ |

| Metal mounting plate | ✓ | ✓ |

| Original Stäubli MC4 connectors | ✓ | ✓ |

4 Specific Questions about Power Optimizer M600-E

Advantages compared to system-dependent optimizers

– Maximum flexibility

• Can be used independently of the inverter

• Partial optimization possible starting from a single optimizer

– Cost savings and increased yield

• Best price-to-performance ratio

• Most efficient technology (patented inactivity of the power electronics when no optimization is needed)

• 20× faster response to shading; efficient optimization using GaN transistors

– Time savings and simplicity

• Easy installation and connection via plug & play

• Installation time per optimizer approx. 2 minutes

• No app setup or initialization required

• No additional components needed

– Highest quality

• Long-life electronics (German engineering)

• Fully encapsulated optimizer

Advantages compared to system-independent optimizers

– Similar product features

• Can be used independently of the inverter

• Partial optimization possible

– Cost savings and increased yield

• Best price-to-performance ratio (lower price)

• Most efficient technology (patented inactivity of the power electronics when no optimization is needed)

• 20× faster response to shading; efficient optimization using GaN transistors

– Time savings and simplicity

• Easy installation and connection via plug & play

• No app setup or initialization required

• No additional components needed

– Highest quality

• Long-life electronics (German engineering)

• Fully encapsulated optimizer

The M600‑E does not have an integrated monitoring function, as it operates without a built-in communication interface. It was designed as a highly efficient and cost-effective solution, focused on the essentials.

For those who require monitoring, the M600‑M can be used, which features a built-in interface for system tracking. In combination with the BRConnect receiver unit, monitoring can then be implemented.

5 Specific Questions about The Power Optimizer M600-M-System

Advantages compared to system-dependent optimizers

– Similar product features

• Easy commissioning without communication dropouts (system setup and data transmission via Power Line Communication/ DC line, not wireless)

– Maximum flexibility

• Can be used independently of the inverter

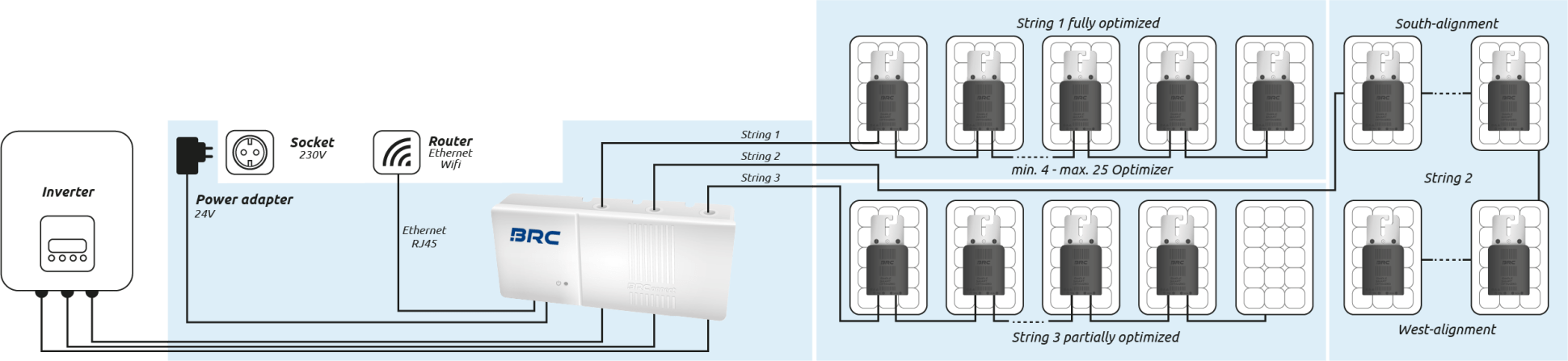

• Partial installation with monitoring possible (min. 4 – max. 25 optimizers per string)

• 1 to 3 strings per gateway can be used

• M600‑M optimizers can also be used without monitoring

• Monitoring function can be retrofitted at any time with a BRConnect

– Cost savings and increased yield

• Best price-to-performance ratio

• Most efficient technology (patented inactivity of the power electronics when no optimization is needed)

• 20× faster response to shading; efficient optimization using GaN transistors

– Reliable and uncomplicated

• Communication between BRConnect and M600‑M optimizers is established without connectors (contactless data acquisition via ring-core coils in BRConnect)

– Maximum data security

• Data stored only on European servers

– Highest quality

• Long-life electronics (German engineering)

• Fully encapsulated optimizer

Advantages compared to system-independent optimizers

– Similar product features

• Can be used independently of the inverter

• M600‑M optimizers can also be used without monitoring (partial optimization from a single optimizer possible)

• Monitoring function can be retrofitted at any time with a BRConnect

– Maximum flexibility

• Partial installation with monitoring still possible (min. 4 – max. 25 optimizers per string required)

• 1 to 3 strings per gateway can be used

– Cost savings and increased yield

• Cost savings through approx. 2 h time reduction when installing a 20 kW system

• Only one additional component needed for monitoring (BRConnect)

• 20× faster response to shading; efficient optimization using GaN transistors

• Most efficient technology (patented inactivity of the power electronics when no optimization is needed)

– Reliable and uncomplicated

• Easy commissioning without communication dropouts (system setup and data transmission via Power Line Communication / DC line, not wireless)

• Communication between BRConnect and M600‑M optimizers established without connectors (contactless data acquisition via ring core coils in BRConnect)

– Maximum data security

• Long-life electronics (German engineering)

• Data stored only on European servers

– Highest quality

• Long-life electronics (German engineering)

• Fully encapsulated optimizer

Communication takes place via Powerline technology directly over the DC line. The performance data of the optimizers is transmitted over the string line and read contactlessly by the BRConnect.

Our system is not designed as a real-time system, but for long-term monitoring of system performance. To provide a simple and cost-effective solution, the data in the app is updated every 15 minutes.

With the M600‑M system, it is also possible to equip only part of a system. However, a minimum of 4 optimizers and a maximum of 25 optimizers per string are required to ensure optimal data transmission.

The M600‑M optimizers can also be used without the BRConnect — in this case, their operation is the same as the M600‑E. Without the BRConnect, there is no minimum number of optimizers required per string.

The BRConnect must be installed between the modules and the inverter. It must not be mounted outdoors. Ideally, the BRConnect is installed near the inverter. Each BRConnect comes with a wall mount, which is attached to the wall with screws. The BRConnect is then placed onto the wall mount.

The string cables are simply passed through the openings of the BRConnect. The direction of the cable feed does not matter — the cables can be routed from top to bottom or bottom to top, depending on what is most suitable for the installation.

Here is a video that briefly explains the installation of the BRConnect:

Only one BRConnect may be used per system. Combining two or more BRConnect units in a single system is not possible.

If your system has a special configuration or specific requirements, please contact our support team directly (support@brc-solar.de) and provide the system details. We will be happy to assist you in planning more complex systems to achieve an optimal and efficient solution with BRC.

At the moment, there is no implementation of a local interface planned.

We will be happy to keep you informed about any updates. The best way to do this is to subscribe to our newsletter. To the Newsletter

An internet connection is required, either via Ethernet or Wi-Fi.

There are no additional fees for using the app.

To make the installation and setup of the system as simple as possible, we have created several setup videos covering the complete commissioning of a system.

You can find the setup videos here:

Installation and commissioning of optimizers: Click here for the video

Part 01: Registration – Power Manager App BRC Solar: Click here for the video

Part 02: Setting up a system – Power Manager App BRC Solar: Click here for the video

Part 03: Functions – Power Manager App BRC Solar: Click here for the video

6 Optimizer Installation

Please always follow the information provided in the user manual. The most important details to consider when planning and installing the individual BRC optimizers can be found in our “Installation Guidelines” for each product:

Also, make sure that the modules and inverters you intend to use are compatible with the respective optimizer model. You can use our checker tools for this:

The optimizers are connected using four plug connections. The following order must be observed: first, the short cables of the optimizer must be connected to the module. Then, the long cables are connected to the preceding or following module or optimizer.

An illustrative guide can be found in our video:

Generally, only one module may be connected to a single optimizer. We currently do not offer a dual optimizer for connecting two modules. If the module voltage is low enough that several modules can be connected in series without exceeding the optimizer’s maximum voltage even at the lowest temperatures, this is possible.

Connecting modules in parallel to a single optimizer is not allowed.

The best indication is an open-circuit voltage test before connecting the strings to the inverter. Our optimizer outputs approximately the open-circuit voltage of the module at its output (long connection cables). If the open-circuit voltage of the string matches the expected open-circuit voltage of the modules multiplied by the number of modules in the string, all optimizers are functioning properly and correctly installed.

-Protective conductor resistance and open-circuit voltage measurements can be carried out without any problems

-A short-circuit current test must NOT be performed when using optimizers, as this can destroy the optimizers.

-For insulation testing, it must be noted that some PV meters in automatic mode connect the two poles of the string together and perform a combined measurement against ground. This is equivalent to a short circuit. Therefore, we recommend performing the insulation test only in manual mode, measuring PV+ against ground and PV‑ against ground separately. In addition, some meters in auto mode always perform a short-circuit current measurement as well.

Important: Any type of short circuit on the string cables must be avoided at all times!

The string + of the optimizer must be connected to the + input of the inverter, and the string – of the optimizer must be connected to the – input of the inverter.

The optimizer must always be surrounded by air to ensure proper cooling. Therefore, a distance of approximately 1.5 cm to 2 cm from the module and other surfaces is required.

7 Inverter / Module Compatibility

Given the large number of inverters available on the market, it is possible that some models are not compatible with our optimizers or are still under testing.

In general, our optimizers are only compatible with string inverters that have one or more MPP trackers for connecting PV strings. The inverter should have global MPP tracking and a suitable input voltage range.

Compatibility approval is provided through the inverter checker.

If a specific device is not listed there, please contact our support team — the inverter may still be undergoing testing.

We recommend keeping the shadow management enabled on all inverter brands, if available, for both full optimization and partial optimization.

During full optimization, the string current can be increased up to the maximum current that the integrated MPP tracker in the inverter allows according to its datasheet.

Explained with the following example (datasheet values):

Module → maximum input current: 10 A

Inverter → maximum input current per MPP tracker: 18 A

Even if the PV modules in this case can only deliver a maximum of 10 A, up to 18 A can flow in the string if the inverter’s integrated MPP tracker allows a maximum current of 18 A. This is because the optimizer always raises the output current to the string current, so the module no longer acts as a limiting factor.

The optimizers are internally limited to a maximum current of 16 A. If an inverter with a higher allowable input current per MPPT is used, the inverter may occasionally request more than 16 A. In such cases, under certain operating conditions, this can trigger a protective shutdown of the optimizers.

This occurs during the automatic search for the global MPP, as the inverter regularly scans the entire characteristic curve of the PV modules and may temporarily reach current levels above 16 A.

If the maximum current of an MPPT tracker according to the inverter datasheet is higher than the allowable maximum current of the optimizers (15 A for the M500, 16 A for the M600‑E/-M), then no more than 50 % of the modules in that string may be equipped with optimizers. With full coverage, the string current could exceed the maximum allowable current of the optimizers, potentially causing the protective shutdown described above.

If the inverter’s MPP tracking is very fast, such overcurrent situations can occur more frequently, which can additionally stress the optimizers over time and, in rare cases, lead to damage.

By equipping a maximum of 50 % of the modules with optimizers, the string power drops significantly as the inverter approaches the short-circuit current of the modules. This prevents the inverter from regulating into higher current ranges.

We have developed a module checker for this purpose. You only need to enter the rated power, short-circuit current, open-circuit voltage, and temperature coefficient, and you will receive feedback on whether our optimizers can be used. You can access the checker here: Click here for the video

Bifacial modules can also be used without any problems with our optimizers. As with non-bifacial modules, you just need to ensure that the module’s power and MPP current under standard test conditions (STC) do not exceed the maximum values specified in the optimizer’s datasheet.

For solar roof tiles or in-roof modules, the voltage of the modules is often significantly lower than the maximum voltage of the optimizers. In this case, a single optimizer may also be connected to a series string of 2 or more of these modules.

The only consideration is that when connecting the solar tiles in series, the sum of the voltages per optimizer must not exceed the maximum voltage of the respective optimizer, taking the temperature coefficient into account.

To be sure, it is best to use our module checker, where you can enter the data of the series-connected tiles. This will give you a direct result on whether the planned setup is compatible with our optimizers.

Our optimizers are also compatible with modules that feature Shading Optimizer Technology / Soft-Breakdown design (e.g., Longi 490 Wp). In many cases, it is advisable to use optimizers with these modules when shading occurs.

With this technology, the modules can not only deactivate one-third of the module via bypass diodes under shading, but it is also possible to bypass a single cell if only that cell is shaded, for example, by a leaf.

However, only the shaded portions of the module are removed from the current path. The energy from these shaded parts remains unused. If a module is more extensively shaded, using optimizers is still worthwhile, as they make the energy from the shaded areas available to the system.

8 Planning Questions

Our optimizer is available in planning tools such as PV*Sol and Solar.Pro.Tool and can be included in system designs.

However, it should be noted that these planning software programs are currently not designed to calculate partial optimization or to provide the economic efficiency of the optimizers.

To optimally support you in your planning at all times, we have developed a series of tools on our website to help you. Things to check include:

Module compatibility → Modul Checker

Here you can easily check whether our optimizers can be used with your module.

Link: Module Checker – BRC Solar GmbH

Inverter compatibility → Wechselrichter Checker

Please always check the compatibility of the individual inverter models with the respective optimizer types before installation.

Link: Inverter-Checker – BRC Solar GmbH

System design → Planungstool

With this tool, you can quickly verify whether the minimum required voltage of your inverter is maintained when using optimizers.

The number of optimizers required and when it makes sense to use them always depends on the system design and the specific situation. It is important to always consider the design of the individual strings.

– Shaded modules in a string:

Only the shaded modules need to be optimized.

Shaded modules should always be equipped with optimizers.

Rule of thumb: Even one hour of shade per day can activate the module’s bypass diodes, which can lead to hotspots on individual cells.

– Different orientations in a string:

When a string includes modules on differently oriented roofs, using optimizers is generally worthwhile.

If approximately 80 % of the modules are on one side, it is sufficient to equip only the remaining 20 % with optimizers.

If there is a more even distribution or irregular orientation, full optimization of the string is recommended.

Special case: North and south sides in one string:

It is sufficient to equip only the north-facing modules with optimizers.

– Different inclinations in a string:

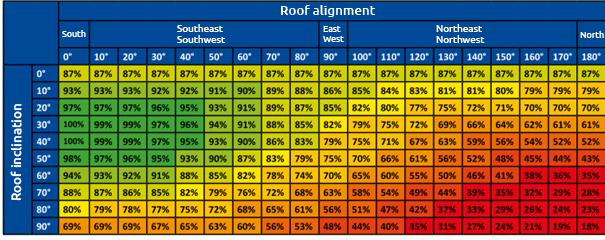

If there is at least a 5 % difference in yield (according to the table), using optimizers is advisable.

If roughly 80 % of the modules share the same inclination, it is sufficient to equip only the remaining 20 % with optimizers.

For larger differences, full optimization is recommended.

(In the graphic: rows show different roof inclinations from 0° = flat; columns show orientations from 0° = perfect south-facing.)

– Different module types:

Always equip the modules with a lower MPP current than the other modules in the string.

Minimum number of optimizers: For optimizers without monitoring (M500 and Mxxx‑E series), the minimum is 1 optimizer.

For the M600‑M optimizers with the monitoring option, at least 4 optimizers per string are required for reliable data transmission to the BRConnect.

Here, the relevant factor is not the module power, but the MPP current. Since the optimizers can increase the current of modules, any module that produces less current needs an optimizer.

If a defective module is replaced with a new module that has a higher MPP current than the other modules, the lower MPP current of the older modules must be balanced using optimizers.

The use of optimizers in parallel-connected strings is not approved. A parallel connection occurs when two or more strings are connected to the same MPP tracker of an inverter.

In parallel-connected strings, the voltage is always electrically identical. However, optimizers can reduce the string voltage situationally — for example, in the case of shading, which can create voltage differences between the strings. This may lead to unwanted back currents between the strings, which in extreme cases can damage or even destroy the optimizers.

If individual modules in parallel-connected strings need to be optimized, these modules must be assigned to a separate MPP tracker. Only a single string (not in parallel) may be connected to this tracker and equipped with optimizers.

This means that for these modules, a dedicated string (without parallel connection) should be formed, containing all modules affected by shading. If there are only a few shaded modules in total, e.g., 2–3 modules, and this string would not reach the inverter’s minimum voltage, additional modules must be added to this string, even if they are not affected by shading, to ensure that the string’s minimum voltage is met.

BRC optimizers can also be retrofitted to existing systems, provided that the modules and inverter are fundamentally suitable. Compatibility with the inverter must always be checked using the Inverter Checker, and module compatibility must be verified using the Module Checker. Additionally, the respective installation guidelines for the optimizers must always be followed.

Option 1: Use our planning tools on the website:

Link: Planning tool – BRC Solar GmbH

Option 2: If you need further support, you can send us the necessary information via our contact form. Our support team will be happy to assist you and handle your request.

Link: Contact – BRC Solar GmbH

Option 3: You can also register for one of our webinars. At the end of each webinar, there is a Q&A session where you can discuss individual topics directly with us.

An optimizer lowers the voltage whenever a module receives temporarily less irradiation than the other modules, while increasing the current so that the module operates at the same current level as the other modules. Therefore, the inverter’s minimum voltage must always be observed. A string should not be designed at the absolute minimum, as temperature effects can further reduce the string voltage.

For safe planning, we recommend using our planning tool, which checks whether the inverter’s minimum voltage is maintained even in worst-case conditions and with active optimizers. The planning tool can be found here:

Planning aids – BRC Solar GmbH

The M600‑E and M500 optimizers may be installed together in a single string. Although we recommend using a uniform type whenever possible (e.g., for new installations), the combination works technically without any issues and is approved by us.

The M600‑M system with the BRConnect communication gateway must always be installed with a single optimizer type. Combining it with other optimizer types in the same string is not allowed.

In pre-alpine and alpine regions, irradiance levels of up to 1100 W/m² to 1300 W/m² are often reached. For this application, we recommend using the M700‑E, which is perfectly suited for these conditions.

It should also be noted that our optimizers can be used without restrictions up to 2,000 m above sea level. At higher altitudes, temperature derating occurs earlier because the optimizer cannot dissipate heat as efficiently.

9 Issues with an Existing System

We have created a guide that shows how to determine whether an optimizer is defective through simple measurements. You can find it here:

Downloads – BRC Solar GmbH

The document is titled: „Prozessanleitung zur Fehleranalyse BRC-Optimierer“

There are two ways an optimizer can behave if it is defective:

a. It completely removes the module it is connected to from the string — in this case, the module’s voltage is missing and the module no longer generates any energy.

b. In rarer cases, it may behave as if no optimizer is installed. In situations of uneven irradiation (e.g., due to shading), the bypass diode will activate, which can be detected by voltage drops caused by the bypass diode activation.

In the event of a defect in an optimizer, we ask the installer to contact us directly. In many cases, we can locate and resolve the problem without having to remove the optimizers.

To do this, simply fill out the form at the following link and select the category “Problem mit einer bestehenden Anlage”:

Contact – BRC Solar GmbH

Once our support team has completed the remote analysis and it is suspected that one or more optimizers may be defective, you will receive an RMA document to include with the return shipment.

After the inspection and fault analysis in our facility, we will inform you of the results.

If a defect is confirmed, we will issue a credit to the wholesaler through whom the optimizers were purchased. Depending on the wholesaler, you will then receive either a credit or replacement optimizers.

If the devices are found to be fully functional, we will proceed according to your instructions on the RMA document: either return the optimizers to you or carry out proper disposal.

10. Purchasing Options

We sell our devices exclusively through wholesalers. Therefore, we cannot provide information about prices or conditions at which you can obtain the optimizers from your wholesaler.

An overview of our wholesale partners can be found on our website:

Our Wholesale Partner – BRC Solar GmbH

If there is no suitable wholesaler listed, you are welcome to send us an order request. We will then contact an appropriate wholesaler who can provide you with an offer for the optimizers.

Submit an order request here:

We sell our devices exclusively through wholesalers. You can find a list of our wholesale partners here:

Our Wholesale Partner – BRC Solar GmbH

If there is no suitable wholesaler listed, you can send us a purchase inquiry. We will try to contact a suitable wholesaler who can provide you with an offer for the optimizers.

You can find the purchase inquiry here:

A list of our wholesale partners can be found here:

https://brc-solar.de/en/power-optimizer-en/our-wholesale-partner/

If there is no suitable wholesaler listed, you can send us a purchase inquiry. We will try to contact a suitable wholesaler who can provide you with an offer for the optimizers.

You can find the purchase inquiry here: